Whether you’ve had the experience of a magnet rusting in your tank, or just heard the horror stories - we’ve set out to simply do it better. Starting with the strongest neodymium N52 magnets possible, we first epoxy coat them as an initial layer of protection. For those magnets going inside your tank, we then encase them in clear acrylic with a specially engineered joint that increases the available seal surface area significantly, while creating a channel where acrylic solvent can easily be applied for consistent, repeatable solvent gluing. Unlike other companies who use opaque or black acrylic or plastic for their magnet enclosures, the transparent acrylic we use allows each magnet enclosure seal to be visually verified, and why we guarantee our internal magnets to never corrode under normal use - ever.

It takes a little longer to CNC cut and solvent weld each of these magnet enclosures - but the goal was to ensure that they would last every bit as long as some of the CoralWalls or other products they are supporting. And because the magnets are out of sight behind the modules, they had to be completely worry free.

-

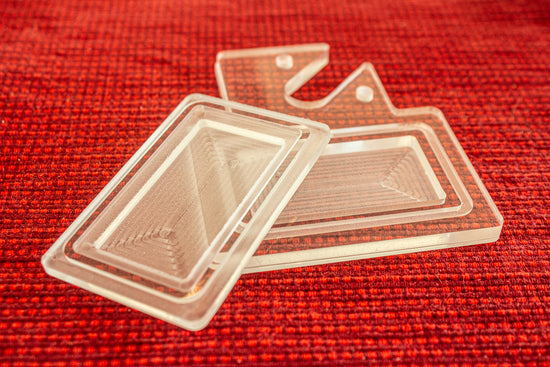

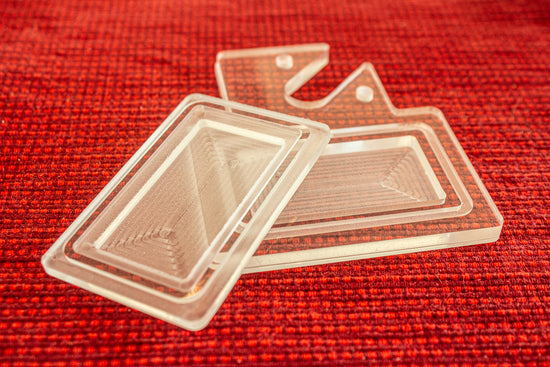

Precision CNC cut magnet enclosures have a special mating groove geometry, which increases the available sealing surface, and contains a reservoir for acrylic solvent.

-

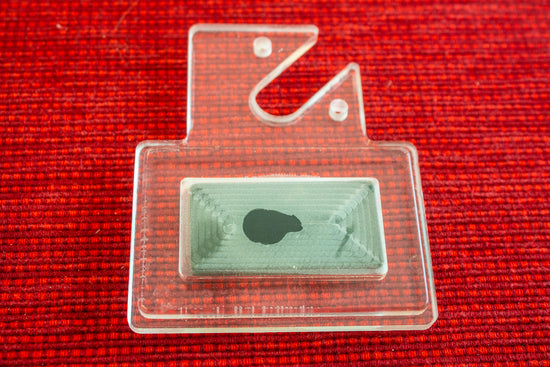

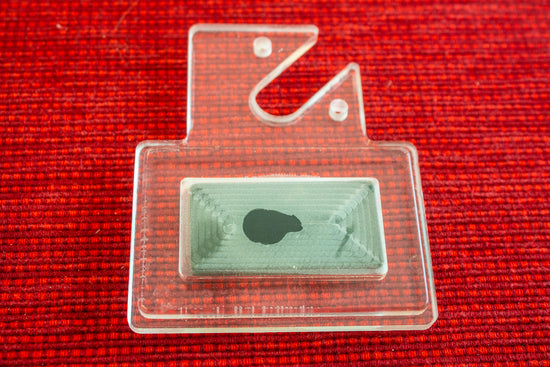

A small dab of silicon is added to the magnet for cushioning and to lock it in place, then the enclosure is solvent welded. Notice the grooved joint has completely disappeared - creating a visually verifiable uninterrupted acrylic seal on all our magnet enclosures.

For external magnets, they have the same black epoxy coating, but we normally don’t enclose them further - for a couple reasons. The epoxy coating will protect the magnets from the occasional splash and drip on the back of your tank or sump. Also, by not enclosing them in additional material - they retain as much of their holding power as possible. Starting at 1/4” (6mm) apart, for each additional 1/16” of an inch (1.5mm) distance between magnets you add by enclosing them in additional plastic or acrylic, you decrease the holding power by approximately 20%. We scale our magnet pairs for the typical aquarium thicknesses of 1/4” (6mm) up to 3/4” (19mm). If you have a special application for thicker than 3/4" aquarium, just let us know and we can likely make it work!

If your external magnet epoxy coating happens to chip through handling or by accidentally attracting an object, simply placing them in a zip lock bag, with the seam pointing downward, before applying them to your aquarium glass will prevent corrosion. (this assumes they are on the back of your tank and out of sight!) Take special care to avoid sudden attractions of metal to the exterior magnets, or magnets to magnets, which can break them or crack their enclosure. Exterior epoxy coated magnets are meant for external use only. Do not submerge them. For special applications, such as mounting modules to the outside of an overflow tower where both magnets will be submerged, we do offer enclosed exterior magnets as well.

Use caution when using our magnets, as they are stronger than you might have experienced before, and can cause damage or injury if not careful. Always slowly slide magnets together or apart. Magnet enclosures can be cracked by dropping them, or by violent attractions of metal objects or other magnets.